Joint product by NETZSCH and OIL DYNAMICS available

Decades ago a German joint product by NETZSCH and OIL DYNAMICS available energy supplier had started to use an underground deposit for gas storage. After a few years, however, it became evident during pumping of the medium that the geological horizon in which it was stored had emitted substantial oil quantities into the gas. This resulted in a conversion from gas to oil production. A suitable pump system had to be acquired in order to reliably transport the crude oil to the surface from a depth of more than 1,200 m.

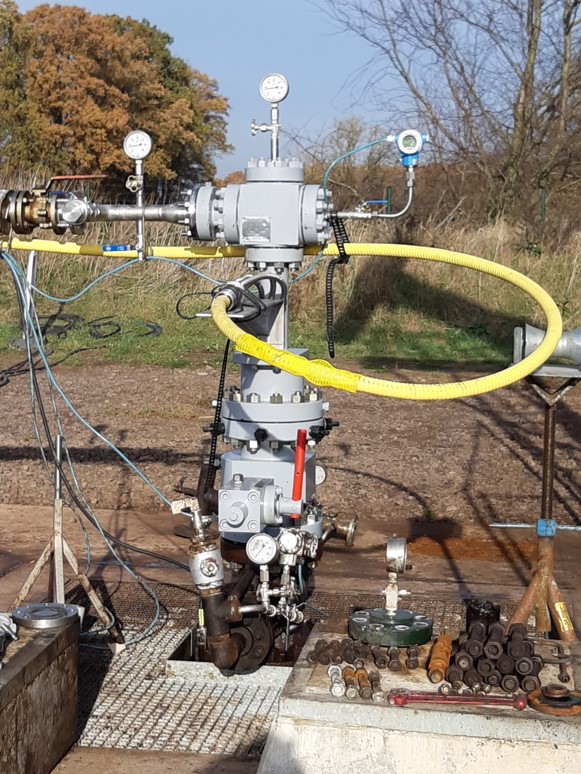

To exclude the possibility of overloading the dynamic seal on the surface and therefore a blowout, NETZSCH suggested the use of the first progressing cavity pump which is driven underground in Central Europe – the NETZSCH ESPCP. The special feature of this special pump, having being designed as a joint project together with OIL DYNAMICS, is that the rotor is not driven via a very long shaft or linkage from a drive head on the surface, but rather the rotor-stator combination and the motor are sunk into the well. The motor or bearing unit is connected directly to the rotor via a flexible rod. All radial and axial forces of the rotor are absorbed by a special underground bearing housing. In addition to this, the dynamic seal is also located in the 1,200 m deep well. This moved all critical components of the pumping solution below ground, precluding environmental impact from leaks above ground. The motor for the system is a permanent magnet model (PMM) with special SPMM control which can ensure flexible flow rates, even with extreme fluctuations of up to 500 percent. Thanks to the PMM motor and the precisely adapted SPSS control, the solution designed by NETZSCH reliably achieves speeds from 100 to 500 rpm. That can ensure the desired flow rate of 1:5 and therefore achieve maximum flexibility.