Electric Submersible Pumps (ESP)

Built to survive ESP systems

We make our ESP systems better than the rest because we know they have to perform in hostile environments, and under the toughest conditions. The result? 100%-reliable, best-in-class-systems, made in Germany, that ease your work and help you to earn better money. They come with a legendary service to rely on.

Turnkey is the key to your success

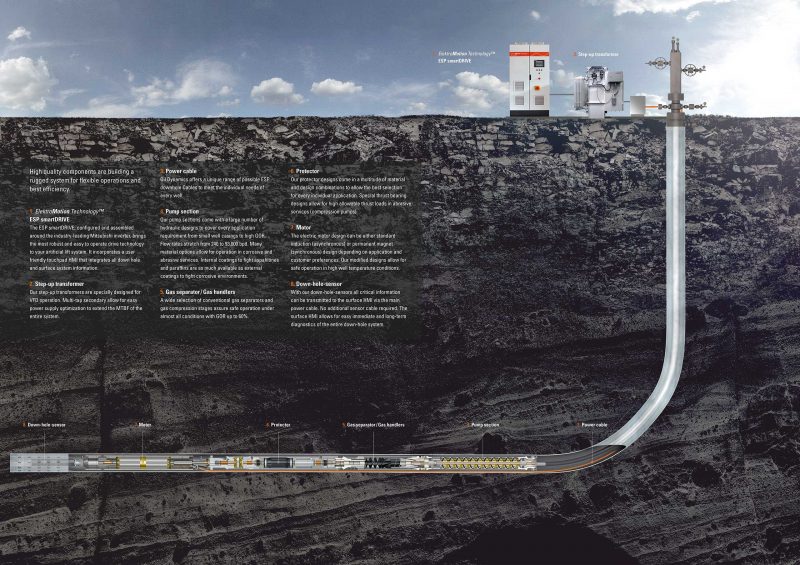

ESP systems are the main artery of crude oil production. As an expert for artificial lift solutions, Oil Dynamics is a provider of powerful answers: We combine best-in-class solutions and materials to build the perfect, tailor-made system fulfilling your needs. We design, engineer, package, test and supply the complete system to pump your fluid to the surface and transfer it through your pipelines.

Our ESP systems come with a variety of specific speed designs that perfectly match your requirements in terms of pressure and production. The ESP can be installed in almost any production well regardless of depth, well inclination and operational conditions. Due to its flexible design with a large variety of technology upgrades like induction and permanent magnet motors, metallurgy and coating options, the ESP is the ideal system to choose. The ESP design will be tailored by our design software to match reservoir conditions and your specific lift and fluid requirements.

Best productivity and reliable performance even through high free gas content at the pump intake

Depending on the well characteristics, additional gas separators and gas handling stages allow for safe operation even in wells with high GOR. A range of down-hole data sensors that transfer all critical system data to the surface combined with a smart monitoring software provide full system transparency and operational control.

Flexible motor concepts

Oil Dynamics offers two different motor technologies both specifically designed for submersible pumping systems in tough production environments: The Induction Motor (IM) and the Permanent Magnet Motor (PMM). While the IM is the workhorse of the industry and will be the perfect choice for most applications, the PMM offers a number of advantages like lower temperature rise, larger shaft diameter and shorter construction that fits the requirements of specific demanding applications.

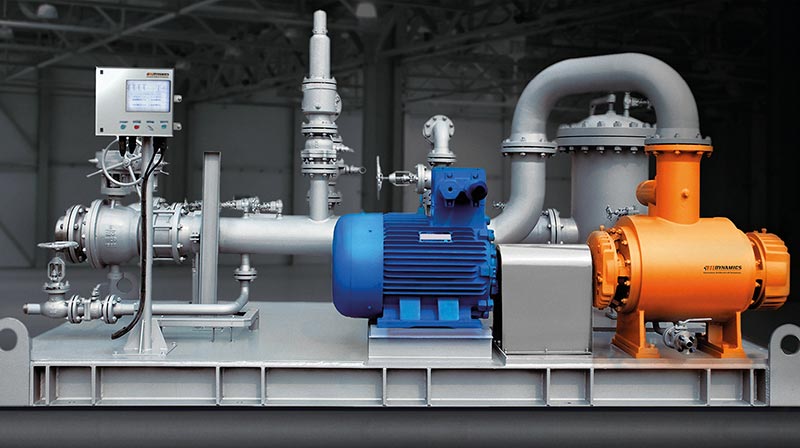

Tailor-made turnkey systems

The choice of the right power generators, variable frequency smartDRIVES (VFD), transformers, surface and down-hole cables, flow meters, control valves and other surrounding material will make sure that your new artificial lift system will work efficient and reliable.

Your key advantages

- Short delivery times: thanks to off-the-shelf components and pre-engineered design

- Tough and proven solution: large array of installations worldwide both, on- and offshore

- Stress resistant technology: stable within harsh conditions with individual upgrades

- Tailor-made system: precisely customized for your needs

- Flexible head generation: multistage pump design allowing for any required combination of head and flow

OIL DYNAMICS GMBH

OFFICE

Rudolf-Diesel-Straße 11 · 69115 Heidelberg · Germany · Phone +49 6221 759770 · Fax +49 6221 7597728 · info@oildynamics.de

FACTORY

Pfälzer Ring 25–29 · 68766 Hockenheim · Germany

OIL DYNAMICS SERVICES S.R.L.

CTParc Bucuresti, Hala F3/C · Dragomiresti Deal · Strada Constanza 21 · Ilfov · Romania